Medical device packaging machines are critical in ensuring medical devices’ safety, sterility, and integrity. These machines are designed to meet the stringent regulatory requirements that govern their packaging, making them an essential part of manufacturing. Understanding the key features of these machines can help manufacturers select the right equipment for their needs.

Precision and Accuracy

Medical device packaging machines are engineered to offer high precision and accuracy in every operation. Given the sensitive nature of medical devices, packaging must be done with the utmost care to ensure that products are not compromised. These machines have advanced sensors and control systems that ensure each package is consistent, sealed correctly, and defects-free.

Compliance with Regulatory Standards

One of the most critical features of medical device packaging machines is their ability to comply with strict regulatory standards. Organizations like the FDA and ISO have set rigorous guidelines for packaging medical devices. These machines are designed to meet these standards by incorporating features like validated sealing processes, controlled environments, and traceability systems.

Flexibility and Versatility

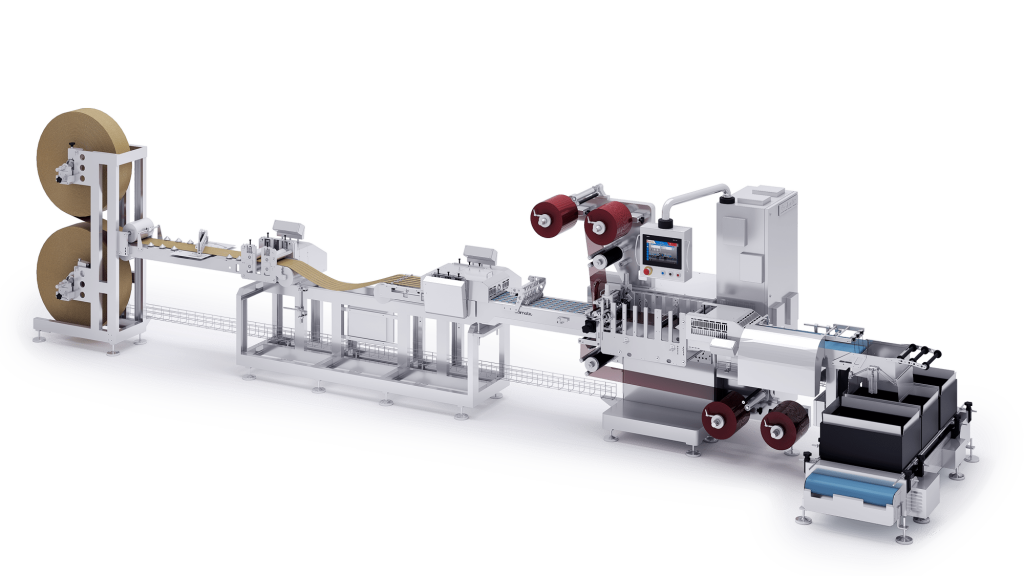

In the medical device industry, packaging requirements can vary significantly depending on the type of device, its size, and the materials used. Medical device packaging machines offer flexibility and versatility to accommodate these variations. They can be easily adjusted or configured to handle different packaging formats, materials, and sizes, ensuring that a wide range of products can be packaged on the same machine.

User-Friendly Interface

Another essential feature of medical device packaging machines is ease of use. These machines often have a user-friendly interface that simplifies operation, reduces the likelihood of human error, and speeds up the packaging process. Touchscreen controls, intuitive software, and programmable settings make it easier for operators to manage the packaging process efficiently.

High-Speed Production

Medical device packaging machines are designed to operate at high speeds without compromising the quality of the packaging. This is crucial for manufacturers who must meet large production quotas while ensuring that every package meets the necessary standards.

Advanced Sealing Technology

Sealing is one of the most critical aspects of medical device packaging. These machines have advanced sealing technology that ensures a secure, sterile seal on every package. Depending on the specific requirements of the medical device, this technology may include features like heat sealing, ultrasonic sealing, or vacuum sealing.

Integration with Quality Control Systems

Packaging machines are often integrated with quality control systems to ensure that every package meets the required quality standards. These systems can include vision inspection systems, leak detection, and automated reject mechanisms that help maintain the highest quality throughout the packaging process.

Energy Efficiency and Sustainability

As sustainability becomes increasingly important in the manufacturing industry, many medical device packaging machines are designed with energy efficiency in mind. These machines use less energy, produce less waste, and are often made from easily recycled materials. This not only helps reduce the environmental impact of the packaging process but can also lead to cost savings for manufacturers.

Conclusion

Medical device packaging machines are sophisticated pieces of equipment designed to meet the high standards of the medical device industry. With features like precision, regulatory compliance, flexibility, user-friendliness, and energy efficiency, these machines ensure that medical devices are packaged safely and effectively. Understanding these key features can help manufacturers choose suitable machines to meet their specific needs and maintain the integrity of their products.

FAQ

1. What are the main functions of medical device packaging machines?

Answer: Medical device packaging machines are designed to ensure that medical devices are securely and hygienically packaged to maintain their sterility and integrity. Their main functions include sealing, labeling, and packing devices into various types of packaging such as pouches, trays, or blisters. These machines help in complying with regulatory standards and extending the shelf life of the products.

2. How do medical device packaging machines ensure sterility?

Answer: Medical device packaging machines ensure sterility through several features. They use heat sealing, ultrasonic sealing, or other advanced sealing technologies to create airtight and tamper-evident packaging. Additionally, many machines are designed to operate in controlled environments, such as clean rooms, to minimize contamination risks. Some also incorporate sterilization processes or are compatible with pre-sterilized materials.

3. What types of packaging formats can these machines handle?

Answer: Medical device packaging machines are versatile and can handle various packaging formats including:

- Pouches: Flexible and often used for single-use items.

- Blister packs: Rigid packaging with cavities for individual devices.

- Trays: Used for bulkier items or multiple devices.

- Clamshells: Two-part packaging that can be heat-sealed.

Machines can often be adjusted or fitted with different molds and tools to accommodate various sizes and shapes of devices.

4. What are some key features to look for in a medical device packaging machine?

Answer: Key features to consider include:

- Precision and Accuracy: Ensures correct filling, sealing, and labeling.

- Automation Level: Automated machines improve efficiency and reduce human error.

- Compliance with Regulations: Meets standards like ISO 13485 and FDA requirements.

- Ease of Cleaning: Designed for quick and thorough sanitation to maintain hygiene.

- Flexibility: Ability to handle different packaging formats and sizes.

- User-Friendly Interface: Simplifies operation and adjustment settings.

5. How do packaging machines integrate with other production processes?

Answer: Packaging machines often integrate with other production processes through automated systems and conveyors. This integration allows for smooth transitions between manufacturing stages, such as from assembly to packaging. Data management systems can synchronize with other production equipment to track and record the packaging process, ensuring consistency and traceability. Additionally, some machines are designed to work in tandem with quality control systems to inspect and verify that the packaging meets all required standards before finalization.