In today’s fast-paced world, the demand for precision manufacturing is at an all-time high. A CNC (Computer Numerical Control) machine shop plays a pivotal role in turning creative ideas into tangible products. From prototypes to large-scale production, these specialized shops have the technology and expertise to bring your visions to life. In this blog, we’ll explore how CNC machine shops operate, the benefits they offer, and how they can help you turn your ideas into reality.

Understanding CNC Machining

What is CNC Machining?

CNC machining is a manufacturing process that uses computer-controlled machines to cut, shape, and mold materials into specific designs. This process allows for high precision and repeatability, making it ideal for various applications, including aerospace, automotive, and medical industries. Unlike traditional machining methods that require manual operation, CNC machining relies on advanced software to automate tasks. This not only speeds up production but also reduces the likelihood of human error.

Note – For those seeking high-quality manufacturing solutions, consider partnering with Raysun, a leading CNC machine shop. With expertise in precision machining and a commitment to delivering exceptional results, Raysun can help transform ideas into reality. Explore how Raysun’s advanced technology and skilled team can elevate projects to the next level. Contact Raysun today to discuss your CNC machining needs and discover the difference in quality and service.

The Importance of Precision

Precision is a critical factor in manufacturing, especially when creating complex parts that must fit together seamlessly. CNC machine shops excel in producing parts with tight tolerances, ensuring that every piece meets the exact specifications required for successful assembly. This level of precision is essential for industries where even the smallest mistake can lead to significant problems. For example, in the aerospace industry, a miscalculated component can jeopardize the safety and functionality of an aircraft. CNC machining mitigates this risk, providing manufacturers with confidence in their products.

The Process of Turning Ideas into Reality

Concept Development and Design

Every great product begins with an idea. The first step in the CNC machining process is to develop a concept and create a design. This often involves collaborating with engineers, designers, or clients to understand their vision and requirements. During this phase, sketches and 3D models are created using computer-aided design (CAD) software. These models provide a clear representation of the final product, allowing for adjustments and refinements before moving on to production.

Material Selection

Once the design is finalized, the next step is selecting the appropriate materials. CNC machine shops work with a variety of materials, including metals, plastics, and composites. The choice of material depends on the intended use of the final product, its durability, weight, and cost considerations. For instance, aerospace components often require lightweight yet strong materials like titanium or aluminum, while medical devices may necessitate biocompatible plastics. The right material is crucial for ensuring that the finished product performs as expected in its intended application.

Programming the CNC Machines

After the design and material selection, the next step is programming the CNC machines. This is a crucial phase, as it involves inputting the specifications into the machine’s computer system. The CNC software translates the CAD model into a series of precise instructions that dictate how the machine should move, what tools to use, and the sequence of operations. This programming ensures that the machining process runs smoothly and accurately. Skilled operators and programmers work together to optimize the program for efficiency and accuracy, minimizing production time while maximizing quality.

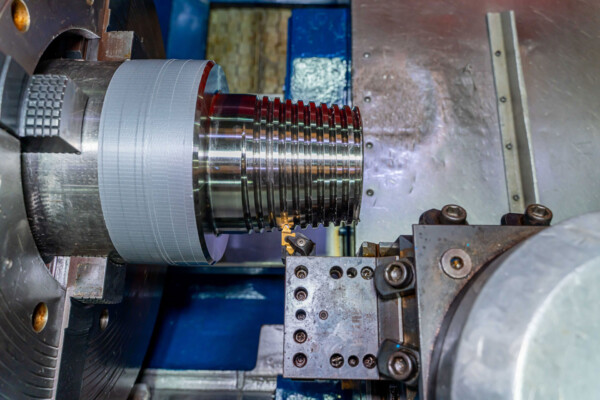

Machining the Part

With the programming complete, it’s time for the CNC machine to bring the design to life. The machining process begins, where the machine cuts, drills, or shapes the material according to the programmed specifications. Depending on the complexity of the part, different tools and techniques may be employed, including milling, turning, and laser cutting. CNC machines can perform multiple operations in a single setup, significantly reducing the time needed for production. As the machine works, operators monitor the process to ensure everything runs smoothly and make adjustments as needed.

Quality Control and Finishing Touches

Once the machining process is complete, the next step is quality control. CNC machine shops have stringent quality assurance protocols to ensure that every part meets the required standards. This often involves measuring the dimensions of the finished product using specialized tools and equipment. If any discrepancies are found, adjustments can be made to the machining process or rework the part to meet specifications. Additionally, finishing touches, such as polishing, anodizing, or painting, may be applied to enhance the product’s appearance and performance. Quality control is vital in maintaining the reputation of the CNC machine shop and ensuring client satisfaction.

The Benefits of Working with a CNC Machine Shop

Enhanced Efficiency

One of the primary advantages of CNC machining is its efficiency. CNC machines can operate continuously without the need for breaks, significantly increasing production rates. This means that ideas can be transformed into physical products more quickly than with traditional machining methods. Additionally, the automation of processes reduces the risk of human error, leading to fewer mistakes and waste. As a result, clients receive their products faster and at a lower cost.

Flexibility in Design

CNC machine shops offer exceptional flexibility when it comes to design changes. If a client wants to modify a design or make adjustments to a part, CNC machining allows for quick updates to the programming without requiring a complete overhaul of the production process. This adaptability is especially beneficial in industries where design changes are common, such as consumer electronics or automotive manufacturing. Clients can be confident that their ideas can be easily implemented, even in the later stages of production.

Cost-Effective Solutions

While CNC machining may require an initial investment in equipment and software, the long-term cost savings can be significant. The efficiency and precision of CNC machining reduce material waste and labor costs, making it a cost-effective solution for manufacturers. Additionally, the ability to produce high-quality parts consistently leads to fewer returns and defects, further enhancing profitability. Clients can rest assured that they are getting the best value for their investment when working with a CNC machine shop.

Access to Expertise

When you partner with a CNC machine shop, you gain access to a wealth of expertise and experience. Skilled machinists and engineers understand the intricacies of the machining process and can offer valuable insights and recommendations. Whether you need help with design optimization or material selection, their expertise can guide you in making informed decisions. This collaborative approach ensures that your ideas are not only realized but also enhanced through the knowledge and skills of the professionals in the shop.

Conclusion

In conclusion, CNC machine shops are instrumental in transforming ideas into reality. From the initial concept to the final product, the process of CNC machining ensures precision, efficiency, and flexibility. With the ability to work with various materials and provide high-quality results, CNC machine shops are essential partners for businesses looking to innovate and succeed in today’s competitive market. By understanding how these shops operate and the benefits they offer, you can leverage their capabilities to turn your creative visions into tangible products. If you have an idea that needs to be brought to life, consider collaborating with a CNC machine shop to make it happen. Your vision is just a step away from becoming reality.

For more insightful articles related to this topic, feel free to visit mstravaloo.com