Its demand has grown substantially over the years, driven by advancements in industrial applications, construction activities, and consumer goods. Understanding the melamine resin price trend is essential for businesses involved in its production, procurement, and consumption. Fluctuations in the price of melamine resin can significantly impact the supply chain, product pricing, profitability, and overall market strategies.

This article provides an in-depth analysis of the factors influencing melamine resin prices, historical price trends, and projections for the future. By gaining insight into these aspects, businesses can make better-informed decisions regarding their supply chain management, procurement strategies, and market positioning.

1. Overview of Melamine Resin

What is Melamine Resin?

Melamine resin is a thermosetting plastic made by combining melamine with formaldehyde through a polymerization process.

Enquire For Regular Prices: https://www.procurementresource.com/resource-center/melamine-resin-price-trends/pricerequest

Applications of Melamine Resin

Melamine resin has a wide range of applications, including:

- Laminates and Coatings: It is widely used in producing laminates for countertops, furniture, and flooring due to its scratch-resistant and heat-resistant properties. It is also used in coating products that require durability and resistance to wear.

- Adhesives: Melamine resin is used in the manufacture of adhesives, particularly in wood products, to improve bonding and strength.

- Molded Products: Melamine resin is used to produce various molded items such as kitchenware, electrical components, and decorative elements due to its durability and heat-resistant properties.

- Textile and Paper Finishing: It is used in treating textiles and papers to impart flame retardancy and improve durability.

2. Factors Influencing Melamine Resin Price Trends

Understanding these drivers is essential to anticipate price fluctuations and manage procurement effectively.

a. Raw Material Costs

The production of melamine resin primarily relies on two key raw materials: melamine and formaldehyde. Fluctuations in the cost of these inputs can significantly affect the price of melamine resin.

- Melamine Prices: Any disruption in the supply of urea or increases in natural gas prices can directly raise melamine prices, and consequently, the price of melamine resin.

- Formaldehyde Prices: Variations in methanol prices due to changes in global demand, supply, and energy prices can affect the overall cost of melamine resin.

b. Energy Costs

Energy consumption plays a significant role in the production of melamine resin. The polymerization process that produces melamine resin requires considerable energy, making energy prices a key cost component.

- Electricity and Fuel Prices: The energy-intensive production process of melamine resin is influenced by electricity and fuel costs. Any fluctuations in global energy prices—whether driven by market forces, geopolitical events, or supply shortages—can lead to corresponding increases in production costs.

- Energy Efficiency: Companies that adopt energy-efficient technologies can mitigate the impact of rising energy costs. However, the initial investment required for implementing energy-efficient systems can be substantial.

c. Supply Chain Disruptions

Supply chain disruptions, including delays in raw material sourcing, transportation issues, or geopolitical factors, can contribute to price fluctuations in melamine resin.

- Logistical Challenges: Transportation delays or shortages in raw materials like urea, ammonia, or methanol can result in supply shortages, driving up production costs for melamine resin. Shipping disruptions, port congestion, and a lack of transportation capacity are significant factors in supply chain inefficiencies.

- Global Trade Policies: Changes in trade policies, including tariffs, import/export restrictions, and sanctions, can also impact the price of melamine resin. For example, any restrictions on the export of urea or formaldehyde-producing feedstocks could affect global supply and push prices higher.

d. Global Demand Dynamics

Demand for melamine resin is driven by various sectors such as construction, automotive, consumer goods, and industrial applications. Fluctuations in demand across these industries can significantly impact melamine resin pricing.

- Construction Sector: The construction industry is a significant consumer of melamine resin, particularly in the production of laminates, coatings, and adhesives. Economic growth, infrastructure development, and urbanization trends in regions such as Asia-Pacific and North America drive the demand for melamine resin. An increase in construction activities leads to higher demand for melamine resin, which can result in price surges.

- Consumer Goods: Melamine resin is commonly used in producing kitchenware, furniture, and household items. Changes in consumer preferences, disposable income, and market trends in the home goods sector can drive shifts in melamine resin demand.

- Automotive Industry: The automotive industry uses melamine resin in various components that require durability and heat resistance. Growth in vehicle production, particularly in electric vehicles, can drive demand for melamine resin in this sector.

e. Environmental Regulations

Regulatory measures aimed at reducing the environmental impact of chemical production can increase the cost of melamine resin production.

- Environmental Compliance: Manufacturers must adhere to environmental regulations related to the production and disposal of chemical waste, emissions control, and energy usage. Compliance with these regulations may require companies to invest in cleaner technologies and waste management systems, which can raise production costs.

- Sustainability Initiatives: As global environmental concerns grow, companies are increasingly looking for sustainable production methods. While greener production processes can reduce long-term environmental impacts, they may involve higher initial costs, which could lead to an increase in the price of melamine resin.

f. Technological Innovations

Technological advancements can lead to more efficient production processes, reducing costs over time. Companies that invest in new technologies may be able to streamline operations, reduce energy consumption, and improve the quality of melamine resin.

- Automation: The implementation of automation in melamine resin production can lead to lower labor costs, greater precision, and increased productivity. By improving operational efficiency, companies can reduce the overall cost of production.

- Research and Development: Ongoing research into alternative production methods and chemical processes may reduce the reliance on expensive raw materials and improve production efficiency, leading to cost savings in the long term.

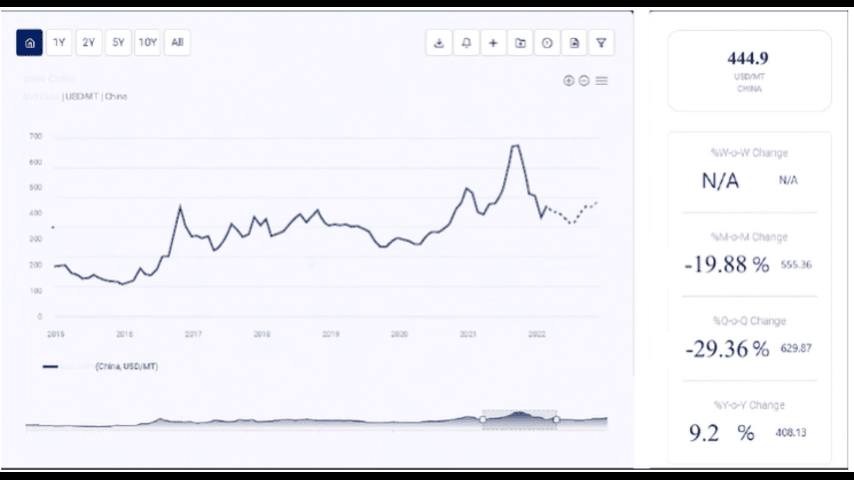

3. Historical Price Trends of Melamine Resin

a. Pre-2020 Stability

Before 2020, melamine resin prices were relatively stable, with only moderate fluctuations driven by seasonal demand and the prices of raw materials like melamine and formaldehyde. The steady demand from construction, consumer goods, and automotive sectors contributed to this stability.

b. Impact of the COVID-19 Pandemic (2020-2021)

The COVID-19 pandemic significantly affected the global melamine resin market, leading to disruptions in supply chains, factory closures, and demand fluctuations. As with many other chemicals, melamine resin prices became volatile during the pandemic.

- Supply Chain Disruptions: Factory shutdowns, transportation delays, and shortages of raw materials such as urea and formaldehyde led to supply constraints in melamine resin production. These factors contributed to price increases during the early stages of the pandemic.

- Demand Fluctuations: While demand from construction and automotive sectors saw a temporary decline during the pandemic, the demand for household goods such as kitchenware and furniture increased as consumers spent more time at home. This demand surge helped stabilize melamine resin prices to some extent.

c. Post-Pandemic Recovery (2022-Present)

As economies began to recover from the pandemic, melamine resin prices started to stabilize, although some factors continued to affect the market.

- Rising Raw Material Costs: The cost of raw materials such as melamine and formaldehyde has increased post-pandemic due to supply chain disruptions, rising energy prices, and inflationary pressures. These increases have contributed to higher production costs for melamine resin.

- Increased Demand: The recovery of the construction, automotive, and consumer goods sectors has driven up demand for melamine resin. Additionally, the rise in green construction and infrastructure projects has boosted demand for laminates and coatings, further increasing melamine resin prices.

4. Future Price Forecast for Melamine Resin

The price outlook for melamine resin will depend on several factors, including the global demand for construction and industrial products, raw material availability, and the impact of energy prices. Here are some key trends to watch:

- Sustained Demand Growth: With continued growth in the construction and automotive sectors, particularly in emerging markets, demand for melamine resin is expected to remain strong. As infrastructure projects and urbanization continue, melamine resin prices may rise in response to increased demand.

Contact Us:

Company Name: Procurement Resource

Contact Person: Leo Frank

Email: sales@procurementresource.com

Toll-Free Numbers:

- USA & Canada: +1 307 363 1045

- UK: +44 7537171117

- Asia-Pacific (APAC): +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA