Investing in metalworking machinery is a critical decision for any manufacturing business, as it directly impacts productivity, efficiency, and product quality. However, purchasing new machinery can be a significant financial burden, especially for small and medium-sized enterprises (SMEs). This is where used metalworking machinery presents a viable and cost-effective alternative. By purchasing used equipment, businesses can save on capital expenditure while still obtaining the tools needed to maintain or even improve their production processes.

However, buying used machinery comes with its own set of challenges and risks. To ensure you’re making a sound investment, there are several key factors to consider before making a purchase. This guide explores the most important aspects to evaluate when buying used metalworking equipment.

1. Understand Your Production Requirements

Before embarking on the journey of purchasing used metalworking machinery, it’s essential to thoroughly assess your business’s production needs. Consider the type of work the machinery will be used for, the material you typically work with, and the precision required. Different machines are suited for various tasks, such as cutting, grinding, forming, or welding. Having a clear understanding of your requirements will help you narrow down your options and choose the equipment that best fits your operations.

Additionally, consider whether you need machinery that can handle high-volume production or whether a smaller, more precise machine will suffice. Determining these specifics will not only guide you in selecting the right used machinery but also prevent over- or under-investment in equipment that doesn’t fully serve your needs.

2. Inspect the Machine’s Condition

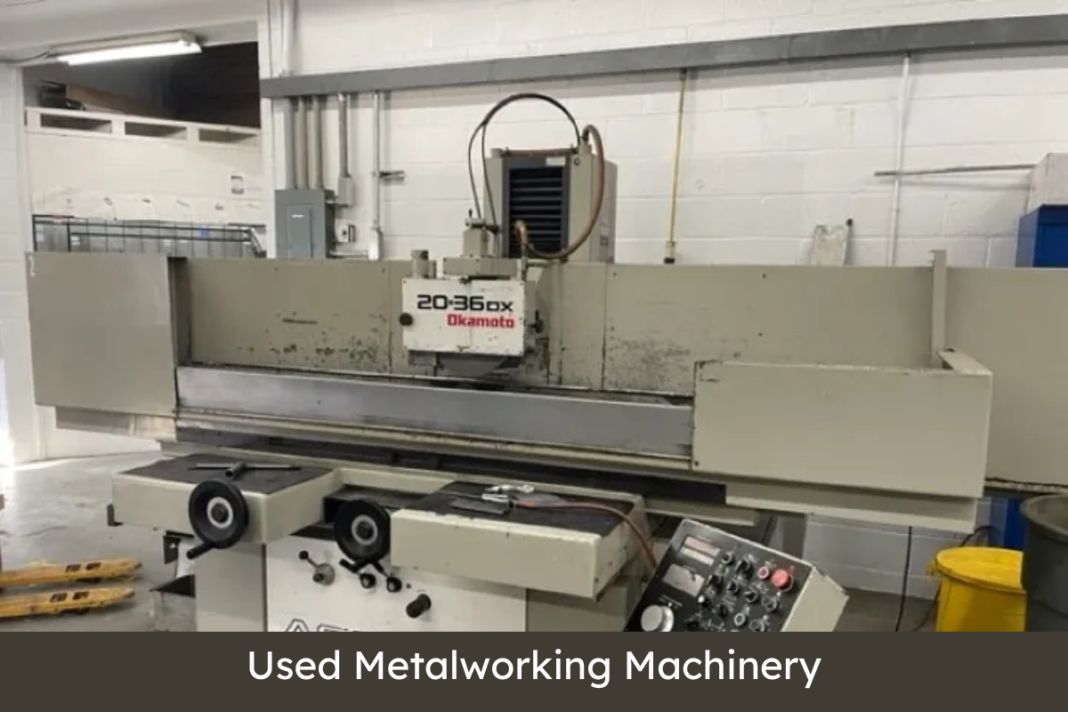

The most crucial factor when purchasing used metalworking machinery is the machine’s current condition. Unlike new machinery, used equipment can have varying degrees of wear and tear, depending on how it was used and maintained by previous owners.

Here are a few aspects to pay close attention to:

- Physical inspection: Look for visible signs of wear, damage, or rust on the machine. Corrosion can indicate poor maintenance or improper storage.

- Operational check: If possible, observe the machinery in operation. Pay attention to unusual noises, vibrations, or any lag in performance, as these may signal underlying mechanical issues.

- Service records: Request the machine’s maintenance and service records. Well-maintained machinery with a documented history of repairs and parts replacements is often a better investment than equipment with an unknown maintenance history.

- Machine age: While age alone should not deter you from a purchase, it’s important to consider the machine’s lifespan and how much longer it can be expected to operate efficiently.

3. Check for Availability of Spare Parts and Support

Another important consideration when buying used metalworking equipment is the availability of spare parts. Older or less common models may have limited access to spare parts, which can result in downtime and reduced productivity if the machine requires repairs. Additionally, some manufacturers may no longer provide technical support or service for outdated models, making maintenance more challenging and costly.

Before finalizing a purchase, check with the manufacturer or parts suppliers to ensure that spare parts are still available and affordable. It’s also wise to confirm whether local technicians are familiar with the machine and can perform maintenance or repairs if needed.

4. Evaluate the Seller’s Reputation

When purchasing used machinery, the reliability of the seller is just as important as the quality of the machine itself. To avoid potential pitfalls, it’s essential to do your homework and vet the dealer or individual selling the equipment.

Here are a few steps to take:

- Online reviews and testimonials: Research the seller’s reputation by reading reviews or contacting previous buyers. Positive feedback from past customers can give you confidence in the seller’s credibility.

- Ask for references: Reputable sellers should be able to provide references upon request. Speak to past customers about their experience with both the equipment and the seller.

- Warranty or return policy: While used machinery often comes with limited warranties, some dealers may offer short-term guarantees or return policies. A seller who stands behind their product will provide you with more assurance in your purchase.

5. Compare Prices and Evaluate Cost-Savings

One of the main reasons businesses opt for used machinery is the potential for cost savings. However, it’s essential to ensure that the lower price point of used equipment doesn’t come at the expense of reliability and long-term value.

When evaluating prices, consider the following:

- Market value: Research the market value of similar used metalworking equipment to determine whether the asking price is reasonable. Prices can vary significantly based on factors like the machine’s age, condition, and features.

- Total cost of ownership: Factor in any additional costs, such as transportation, installation, and potential repairs. A machine with a lower upfront cost might require expensive repairs or part replacements shortly after purchase.

- Financing options: Some sellers may offer financing or leasing options for used equipment. Depending on your financial situation, these options could provide more flexibility and allow you to invest in higher-quality machinery without straining your budget.

6. Assess Compatibility with Current Operations

When purchasing used metalworking machinery, it’s crucial to ensure that the equipment will integrate seamlessly with your existing operations. This includes verifying that the machine is compatible with your facility’s electrical and space requirements. For instance, some older machines may require different power supplies or more floor space than modern equipment.

You should also consider whether the machine will require upgrades or modifications to meet safety standards. Depending on the equipment’s age and model, it may not comply with the latest safety regulations, and retrofitting can add to your overall costs.

7. Consider Future Expansion Needs

While your current production needs may guide your purchase decision, it’s also important to think about future expansion. If your business is likely to grow or diversify its operations, you’ll want to choose equipment that can scale accordingly. Opting for versatile or modular machinery that can handle a variety of tasks may provide more long-term value than a machine designed for a single purpose.

Conclusion

Purchasing Used Metalworking Equipment can offer significant cost savings and provide your business with the tools needed to maintain competitive operations. However, the key to a successful purchase is thorough research and careful evaluation of all factors, including machine condition, spare parts availability, seller reputation, and compatibility with your current and future needs. By keeping these key factors in mind, you’ll be well-equipped to make a smart investment that benefits your business in the long run.