PLCs have been evolving since their inception in the 1960s, and there are several trends and innovations to watch out for in the future. Some of the notable ones include:

Industrial IoT:

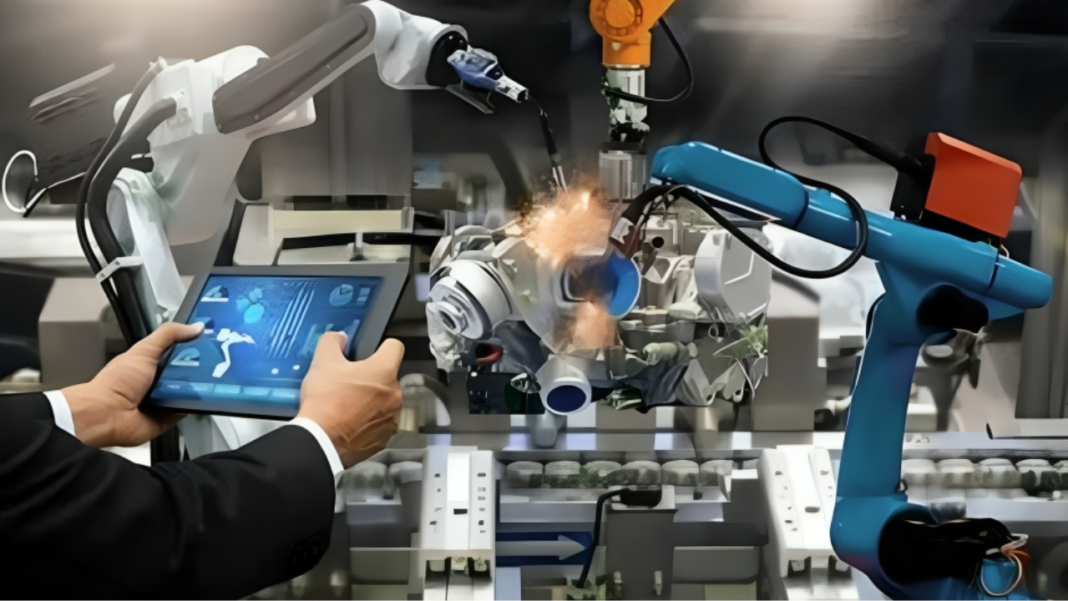

The integration of programmable logic controller (PLC) with the Industrial Internet of Things (IIoT) will enable real-time monitoring, predictive maintenance, and enhanced automation capabilities.

The automation industry is following the Industrial Internet of Things (IIoT) trend, which entails connecting various industrial machines and devices to the internet so they can communicate and carry out automated tasks more intelligently and effectively. IIoT enables businesses to streamline operations, cut downtime, and boost productivity by utilizing sensors, cloud computing, and other cutting-edge technologies. This development of more intelligent and connected PLC systems that can integrate with a variety of other technologies, including machine learning, big data analytics, and artificial intelligence, is being driven by this trend.

Edge Computing:

Edge computing allows data processing to occur closer to the source of data, reducing latency and improving system responsiveness. This can enable more efficient and effective control of industrial processes.

Instead of relying on centralized cloud computing resources, edge computing is a distributed computing model that moves data processing and analysis closer to the source of the data. By allowing data processing and analysis to be done at the network’s edge, closer to the PLC and the devices it is controlling, edge computing can help PLCs reduce latency and improve real-time control. This can aid in enhancing the efficiency and dependability of PLC operations, particularly in settings with patchy or unstable internet connectivity. PLCs can now perform real-time data analysis and make independent decisions without the need for external computing resources thanks to the development of edge computing technologies.

Artificial Intelligence:

The use of AI in PLCs can improve decision-making capabilities and enable more complex automation tasks.

A branch of computer science known as artificial intelligence (AI) is devoted to creating computer programs that are capable of performing tasks that would typically require human intelligence, such as speech recognition, visual perception, decision-making, and language translation. AI can be applied to PLCs to increase the precision and effectiveness of control systems, enabling them to adjust to changing circumstances and continuously improve performance. AI algorithms can be used, for instance, to anticipate maintenance requirements and plan downtime, spot anomalies in machine performance and notify operators of potential problems, or enhance production processes by examining sensor data and making real-time control parameter adjustments. As AI technology develops and becomes more widely available.

Cloud Computing:

Cloud computing can enable remote access and monitoring of PLCs, as well as facilitate the integration of multiple systems and data sources.

Delivering computing services, such as servers, storage, databases, networking, software, and analytics, over the internet or “the cloud” is known as cloud computing. Organizations can access and utilize computing resources on demand with cloud computing without having to invest in costly infrastructure. Cloud computing is becoming more widely used across a variety of industries, including manufacturing and industrial automation. It can provide many advantages, including cost savings, scalability, and flexibility. Cloud computing can be applied to PLCs for data storage, analysis, and remote access.

Check :- Rockwell Automation MicroLogix 1400 PLC

Cybersecurity:

As PLCs become more connected and integrated with other systems, cybersecurity will become increasingly important to protect against potential threats and attacks.

Delivering computing services, such as servers, storage, databases, networking, software, and analytics, over the internet or “the cloud” is known as cloud computing. Organizations can access and utilize computing resources on demand with cloud computing without having to invest in costly infrastructure. Cloud computing is becoming more widely used across a variety of industries, including manufacturing and industrial automation. It can provide many advantages, including cost savings, scalability, and flexibility. Cloud computing can be applied to PLCs for data storage, analysis, and remote access.

Wireless Connectivity:

The use of wireless connectivity technologies, such as 5G and Wi-Fi 6, can enable more flexible and mobile industrial systems.

To enable communication between PLCs or between PLCs and other devices, wireless connectivity in the context of PLCs refers to the use of wireless communication technologies like Wi-Fi, Bluetooth, or cellular networks. Physical cabling, which can be time-consuming and expensive to install, can be replaced by wireless connectivity, allowing remote access to and monitoring of PLC systems. However, using wireless connectivity can also present security risks, so appropriate precautions must be taken to guarantee the system’s security. Additionally, environmental factors like interference or signal loss can interfere with wireless communication, so wireless device placement and design must be carefully thought out.

Open Standards:

The adoption of open standards, such as OPC-UA and MQTT, can improve interoperability between different industrial systems and facilitate data sharing and integration.

Open standards are consensus-based, freely available, and vendor-neutral technical specifications that outline how various technologies should communicate with one another. PLCs can be interoperable with other systems and devices in the industrial automation ecosystem as well as with PLCs of various types and brands thanks to open standards. For end users, open standards can help reduce costs, boost flexibility, and lessen vendor lock-in. OPC UA, EtherCAT, and MQTT are a few open standards that are pertinent to PLCs.

Overall, increased connectivity, intelligence, and flexibility, as well as a stronger emphasis on cybersecurity and open standards, are anticipated to characterize PLCs in the future.