3D printers are incredible tools for creating prototypes, models, and more. However, they can also be noisy, especially when running for hours at a time. The constant hum of motors and fans can be distracting or even disruptive in home or office environments. One effective way to tackle this issue is by using an enclosure specifically designed to reduce noise. Let’s dive into how enclosures can help you create a quieter workspace while improving your overall 3D printing experience.

Why Do 3D Printers Make Noise?

3D printers generate noise due to several components working simultaneously. The primary noise sources include:

- Stepper Motors: These control the movement of the printer’s axes, producing vibrations and hums.

- Fans: Both cooling fans for the hot end and extruder add to the overall sound level.

- Print Bed Movement: The rapid movement of the print bed contributes to additional noise.

While the noise level varies depending on the type of printer, it can be significant enough to warrant a solution, especially in quieter environments.

What Is a 3D Printer Enclosure?

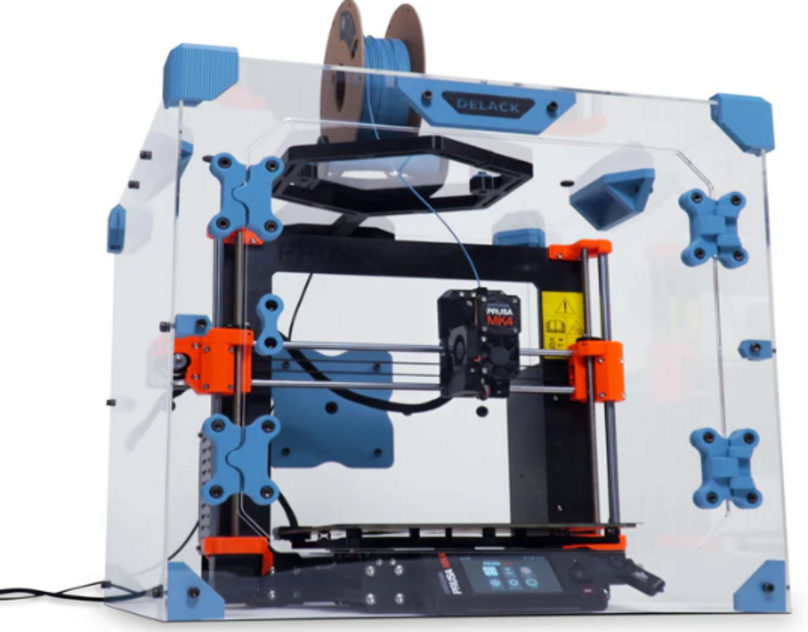

A 3D printer enclosure is a protective housing that surrounds the printer. While the primary goal of most enclosures is to control the printing environment by maintaining temperature and preventing dust, they can also significantly reduce noise levels. By creating a physical barrier, enclosures absorb and deflect sound waves, making the printer much quieter during operation.

How Does an Enclosure Reduce Noise?

Enclosures reduce noise by:

- Absorbing Vibrations: The walls of the enclosure act as barriers that absorb vibrations caused by the stepper motors and moving parts, reducing the transfer of sound.

- Blocking Sound Waves: Enclosures block the sound waves generated by the printer, keeping the noise inside rather than allowing it to spread throughout the room.

- Damping Materials: Enclosures often use materials like foam or dense panels that are excellent at damping noise, further reducing sound levels.

Choosing the Right Enclosure for Noise Reduction

Not all enclosures are created equal, so if noise reduction is your main goal, look for an enclosure with the following features:

- Dense Materials: Materials like MDF (Medium-Density Fiberboard), acrylic, or even sound-dampening foam can greatly reduce noise.

- Tight Seals: Gaps or poorly sealed doors will let noise escape. Choose an enclosure with tight-fitting doors or magnetic seals.

- Vibration Dampening Feet: Some enclosures come with vibration dampening feet that isolate the enclosure from the surface it sits on, preventing the transmission of vibrations.

DIY vs. Pre-made Enclosures for Noise Reduction

You can either purchase a pre-made enclosure designed specifically for your printer or build your own. Both options have pros and cons:

- Pre-made Enclosures: These are often optimized for sound and thermal control but can be expensive. They come with built-in features like ventilation and soundproofing materials.

- DIY Enclosures: If you’re on a budget or have specific requirements, a DIY enclosure can be a great option. Using soundproofing materials such as foam panels, acrylic sheets, or even blankets can offer considerable noise reduction. Just make sure to account for ventilation and accessibility.

Adding Soundproofing to Your Enclosure

If you’re building a DIY enclosure or looking to enhance a pre-made one, you can add soundproofing materials for extra noise reduction. Consider:

- Acoustic Foam: Attach foam panels to the inside of your enclosure. They absorb sound waves and reduce noise effectively.

- Mass Loaded Vinyl: This dense material is excellent for soundproofing and can be added to the enclosure walls.

- Rubber Feet: Adding rubber feet to the enclosure or printer itself can further reduce vibrations transmitted to the surface underneath.

Ventilation and Noise Control

While reducing noise is essential, it’s also important to maintain proper ventilation inside the enclosure. Overheating can lead to poor print quality or even damage the printer. Some ways to ensure proper airflow include:

- Ventilation Holes: Add small ventilation holes to ensure air circulation without significantly impacting noise levels.

- Quiet Fans: If your enclosure uses fans, choose low-noise models to prevent adding more sound while maintaining airflow.

Does Noise Reduction Affect Print Quality?

Interestingly, reducing noise can also enhance print quality. Enclosures designed for noise reduction often minimize vibrations and external factors, leading to more stable printing conditions. This can result in fewer errors, better adhesion, and more consistent prints, especially when working with materials like ABS or nylon that benefit from a controlled environment.

Maintaining a Noise-Reduction Enclosure

To keep your enclosure performing optimally, regular maintenance is important. Clean the inside of the enclosure frequently to prevent dust buildup. Check the seals around doors and windows to ensure they are still tight and prevent noise from escaping. If you’re using soundproofing materials, replace them when they become worn out.

Conclusion: A Quieter 3D Printing Experience

Using an enclosure designed for noise reduction is one of the most effective ways to minimize the disruptive sounds of 3D printing. Whether you build your own or invest in a pre-made model, the benefits are clear—less noise, better print quality, and a more pleasant environment. By choosing the right materials and adding proper ventilation, you can achieve a quieter 3D printing experience without sacrificing performance.

For more information click here