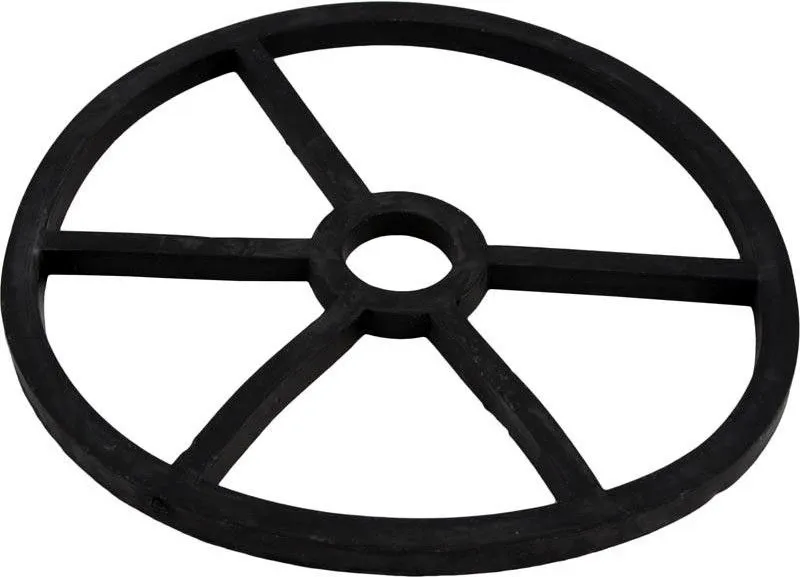

Spider gaskets play a critical role in enhancing the overall performance of mechanical systems. These highly effective sealing components are designed to maintain a tight, leak-proof seal in high-pressure, high-temperature environments. When properly installed, a Spider Gasket ensures the system operates smoothly by preventing unwanted fluid or gas leakage. Its unique design allows for flexibility, ensuring that it adapts to different shapes and sizes of equipment, while minimizing wear and tear.

Why Spider Gaskets Are Essential for Reliable Sealing

Spider gaskets revolutionize sealing technology. Their innovative design enables them to perform exceptionally well in demanding environments. They ensure systems remain leak-free and efficient.

Capable of handling extreme temperatures and pressures, spider gaskets provide reliable sealing solutions. They cater to a wide range of industries, from automotive to industrial machinery.

Exploring the Different Types of Spider Gaskets

Not all Spider Gaskets are the same. Various types exist to meet the specific needs of different industries. For example, the T500 Spider Gasket is designed for high-performance applications. It offers superior sealing capabilities in challenging conditions. Whether sealing equipment in the food industry, chemical plants, or automotive machinery, there’s a Spider Gasket tailored to your needs.

When choosing a Spider Gasket, understand the different materials, thicknesses, and designs available. A high-quality gasket ensures system integrity and performance. Selecting the right one is crucial for optimal results.

4o mini

Key Qualities to Look for in a High-Performance Spider Gasket

When searching for a high-performance Spider Gasket, consider several important qualities. First, choose gaskets made from durable materials that withstand harsh environments. Temperature and pressure resistance are crucial for ensuring long-term reliability. Flexibility is also key, as it allows the gasket to adapt better to system movements.

Common Applications and Uses of Spider Gaskets

Spider Gaskets are used in a wide range of applications across multiple industries due to their versatility and reliability. Commonly found in automotive engines, HVAC systems, and industrial machinery, Spider Gaskets are essential for preventing leaks and maintaining operational efficiency. Their unique design makes them particularly suitable for systems that experience vibration or movement, ensuring a secure seal despite shifting parts.

Maintenance and Care: Ensuring Longevity of Your Spider Gaskets

Maintaining your Spider Gaskets is crucial for ensuring their long-term performance. Regular inspection is essential to detect wear or signs of degradation that could lead to leaks. Over time, exposure to high temperatures and pressure can cause gaskets to lose their sealing ability, so replacement might be necessary.

To ensure your Spider Gasket lasts as long as possible, it’s important to clean it regularly and check for any physical damage. If you notice any signs of leaks or unusual performance, it’s best to perform a Spider Gasket replacement before the issue escalates. By taking care of your Spider Gasket, you can maximize its lifespan and continue benefiting from its high-quality sealing capabilities.

The Role of Spider Gaskets in Improving System Efficiency

Spider Gaskets are integral to the efficiency of your system. By maintaining a strong and consistent seal, these gaskets prevent fluid and gas losses that could lead to energy waste or system inefficiency. A compromised seal can result in reduced pressure, loss of materials, and higher operational costs.

Understanding the Importance of Spider Gaskets in Industrial Systems

Spider gaskets are critical components in ensuring the seamless operation of various mechanical systems. They play an essential role in maintaining the integrity of the system by providing effective seals that prevent unwanted fluid or gas leakage. Without spider gaskets, systems would be prone to contamination, inefficiency, and potentially hazardous failures. Their design is specifically engineered to endure high-pressure and high-temperature environments, making them invaluable in industries where system reliability and safety are paramount.

Why Spider Gaskets Are a Game-Changer for Sealing

What sets spider gaskets apart from other sealing solutions is their ability to operate in demanding conditions without compromising on performance. These gaskets are designed to withstand extreme pressures and temperatures, making them suitable for a variety of high-stakes applications. Whether used in automotive engines or chemical processing plants, spider gaskets ensure that systems stay leak-free, reducing the risk of accidents and enhancing overall efficiency. Their resilience under challenging conditions makes them indispensable for industries requiring top-tier sealing performance.

Different Types of Spider Gaskets for Various Applications

Spider gaskets come in various types, each designed to meet the unique needs of different industries. For example, the T500 Spider Gasket is specifically designed for high-performance applications where reliability and durability are crucial. In the automotive industry, these gaskets provide optimal sealing for engine components, while in the food and chemical industries, they ensure tight seals in processing equipment. When choosing a spider gasket, it’s essential to consider factors like material composition, thickness, and flexibility to ensure you get the right gasket for your specific application.

Key Qualities to Look for in a Spider Gasket

When selecting a spider gasket, it’s important to focus on several key qualities. Durability is paramount, as the gasket must endure harsh environmental conditions, such as high temperatures, pressures, and exposure to chemicals. Flexibility is another critical feature, allowing the gasket to maintain a secure seal even when subjected to vibrations or shifting equipment. Additionally, a high-quality spider gasket should have excellent chemical resistance, ensuring that it remains effective in a variety of industrial settings. Paying attention to these qualities will help you choose a gasket that will perform reliably and last longer.

Common Uses and Applications of Spider Gaskets

Spider gaskets are versatile and can be found across multiple industries, including automotive, HVAC, and industrial machinery. In automotive engines, they prevent leaks in critical components, while in HVAC systems, they help maintain air and fluid seals to improve system performance. These gaskets are especially effective in environments with constant movement, vibration, or pressure changes. Their ability to adapt to different shapes and sizes of equipment while maintaining a tight seal makes them invaluable in industries that require high-performance, long-lasting sealing solutions.

How to Maintain Your Spider Gaskets for Optimal Performance

Proper maintenance of your spider gaskets is essential to ensure they provide long-term sealing performance. Regular inspections should be carried out to detect any wear and tear, especially in high-pressure or high-temperature environments where gaskets can degrade faster. Cleaning the gaskets and checking for physical damage, such as cracks or deformation, will help identify issues early on. If you notice any leaks or performance issues, it’s best to replace the gasket promptly to avoid further damage to the system.

The Impact of Spider Gaskets on System Efficiency

Spider gaskets contribute significantly to the efficiency of a system by ensuring that seals remain intact, preventing costly leaks of fluids or gases. When gaskets fail, energy and materials are wasted, which can result in lower efficiency, increased operational costs, and potential system breakdowns. By maintaining a strong seal, spider gaskets help ensure that systems run smoothly, reducing downtime and maintenance costs. They also help in preserving system pressure and preventing the loss of valuable resources, ultimately improving overall operational efficiency.

Why Pond Owners Trust Grand Champion Technologies (GC Tek)?

When it comes to Spider Gaskets, GC Tek offers some of the best solutions available. The T500 Spider Gasket from Grand Champion Technologies (GC Tek) is designed with precision and quality in mind, providing unmatched durability and performance. GC Tek’s commitment to excellence ensures that their Spider Gaskets are ideal for a wide range of industrial applications, offering reliable sealing even in the most challenging conditions.